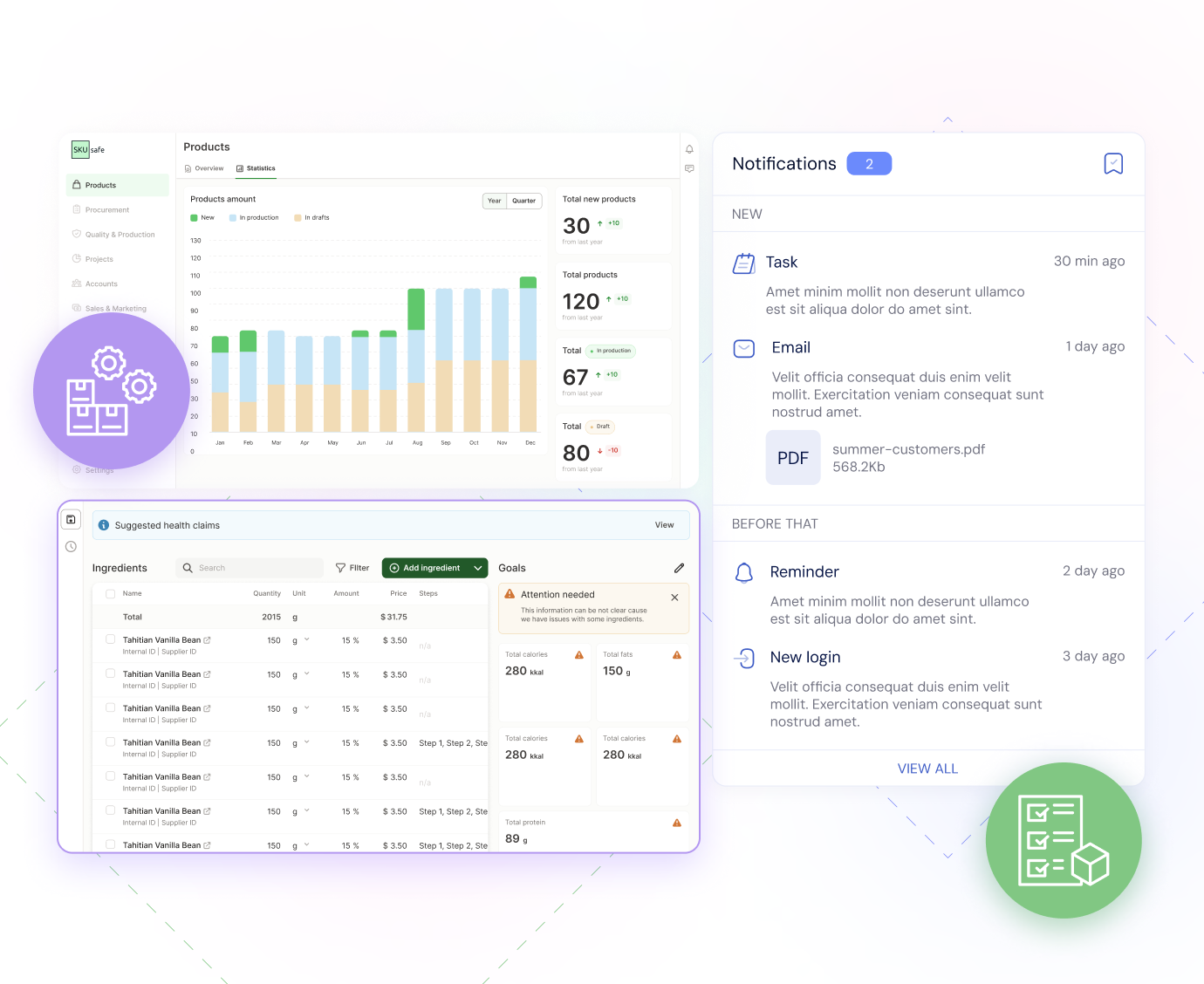

Inventory Management Software Development Services

Uitop builds custom software that helps businesses monitor their inventory. We focus on easy designs and straightforward language, so everyone on your team can use the software easily. Plus, we’re always here to lend a hand if you have any questions or need some adjustments.

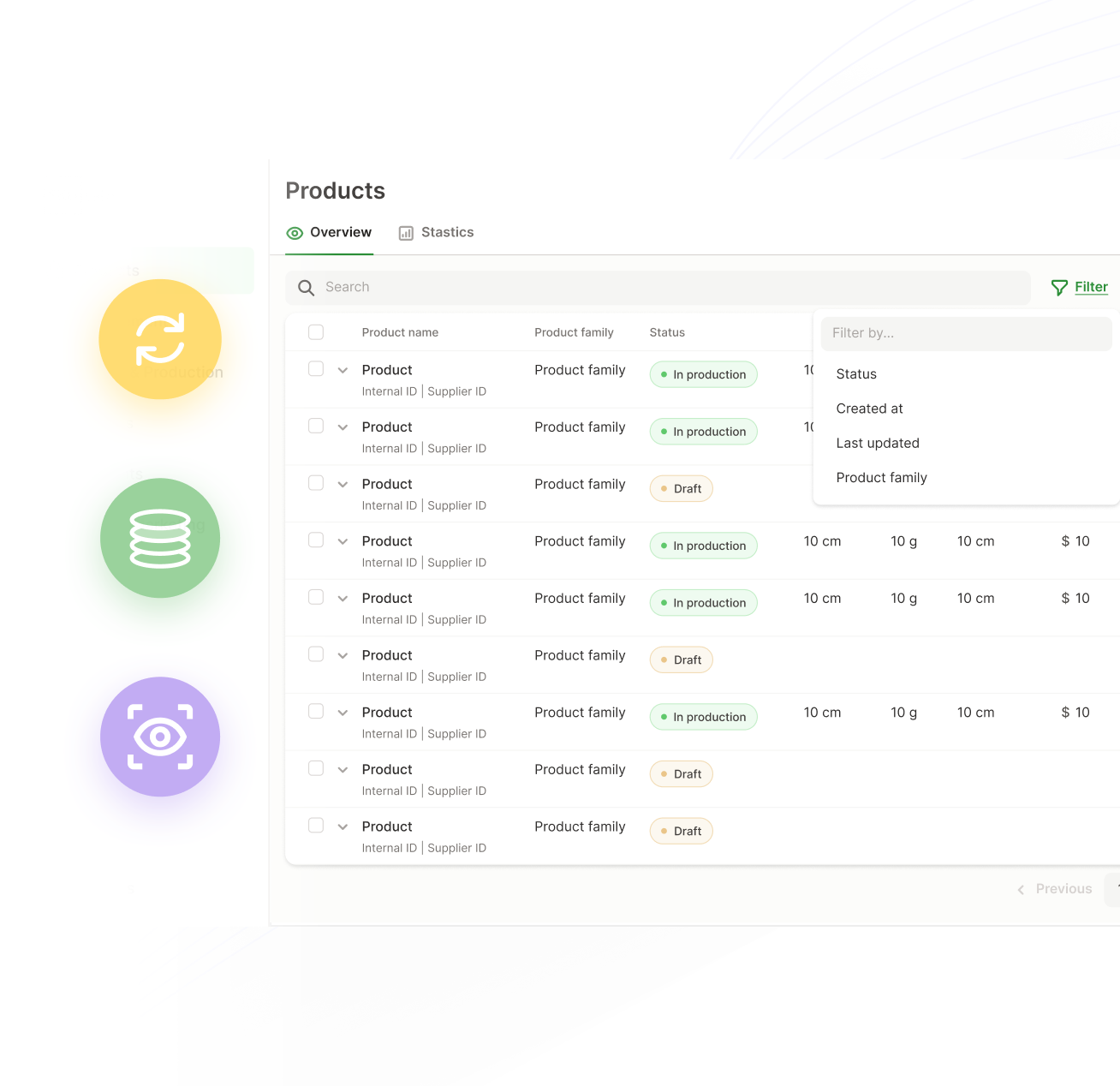

Benefits of Custom Inventory Management Software

Real-Time Inventory Tracking

Accurate Stock Levels

Stay on top of your stock levels with real-time inventory tracking. This feature gives you an instant view of your inventory. By keeping stock levels precise, you can make smarter inventory decisions and boost your bottom line.

Multi-Local Synchronization

With multi-location synchronization, you can smoothly update your inventory data across all your locations. It lets you transfer stock easily between locations and gives you a complete picture of your inventory.

Automated Data Collection

Real-time inventory tracking also uses automated data collection tools. This could mean barcode scanning, RFID tech, or IoT sensors to keep inventory levels updated automatically. Automated data collection cuts down on mistakes and saves time that would have gone into manual counts.

Real-Time Inventory Tracking

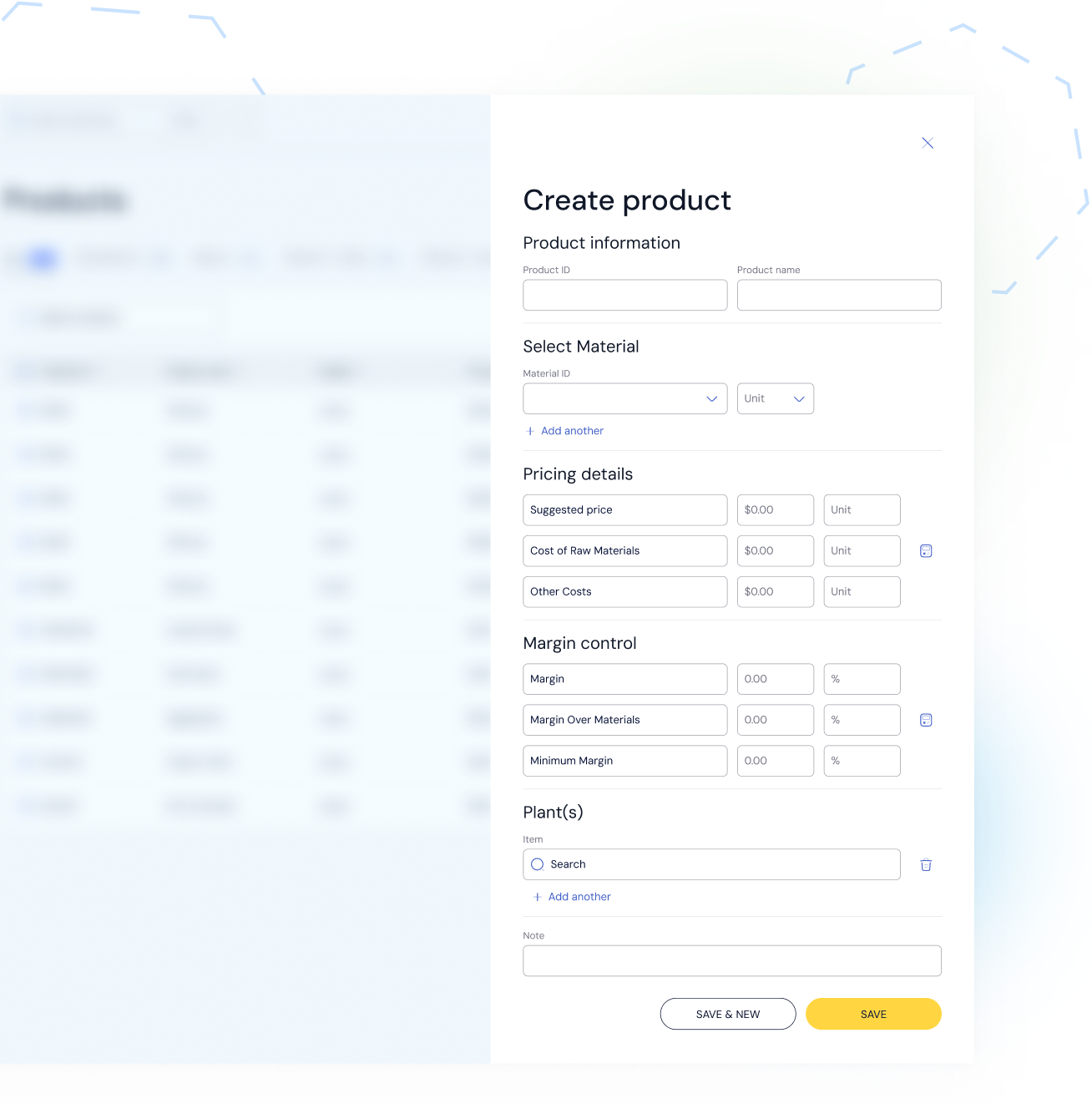

Purchase Order Management

Automate Reorder Points

This feature creates purchase orders whenever your inventory reaches a specific level. It considers lead times, seasonal demand, and past sales data. With automated reorder points, you’ll never run out of stock, and you’ll also avoid having too much inventory.

Vendor Performance Tracking

Vendor performance tracking lets you monitor your suppliers’ performance over time. It logs delivery times, order accuracy, and product quality. By keeping a detailed history of vendor performance, you can make smarter choices about who to work with.

Order Consolidation

Order consolidation is another handy feature of purchase order management. It involves merging multiple orders from the same supplier, which saves on shipping costs and makes receiving inventory much easier.

Purchase Order Management

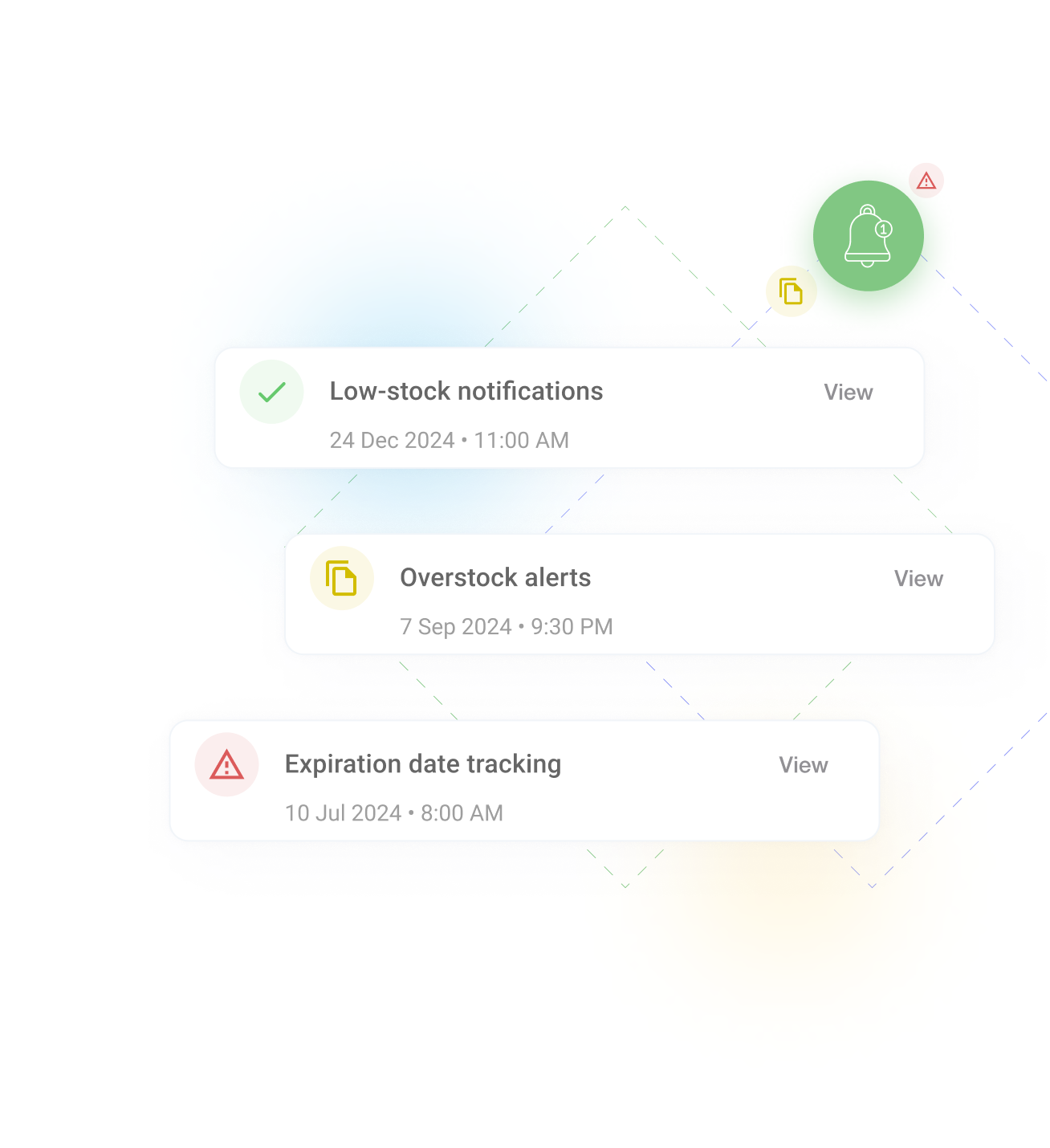

Stock Level Alerts and Notifications

Low-Stock Warnings

With low-stock notifications, you’ll know when your inventory dips below a certain point. You can tweak these alerts based on what kind of product it is, where it’s located, or if there’s a seasonal demand. These alerts are great for avoiding stockouts because they remind you to reorder just in time.

Overstock Alerts

Overstock alerts help you avoid having too much inventory on hand, which saves you money and lowers the chance of goods becoming outdated. By keeping an eye on overstock, you can make the most of their inventory and use your warehouse space wisely.

Expiration Date Tracking

Expiration date tracking is a lifesaver for businesses that sell perishable goods or items with expiration dates. It sends you alerts as products near their expiration dates. This feature helps keep product quality in check and aids in planning timely deals or discounts for items that are about to expire.

Stock Level Alerts and Notifications

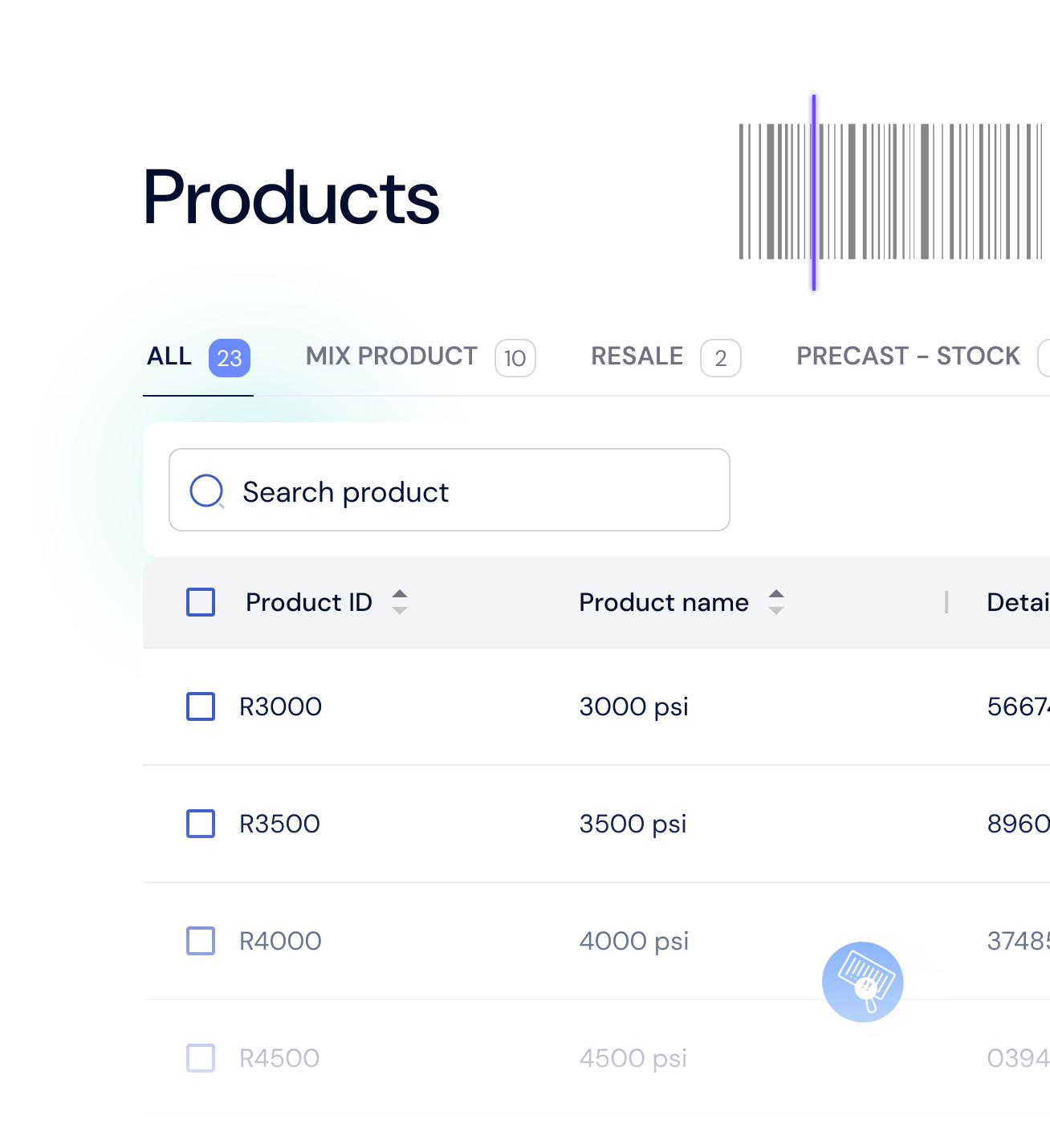

Barcode Scanning and RFID Integration

Mobile Scanning Capabilities

Your warehouse staff can use their smartphones or special handheld devices to scan barcodes and update inventory in real-time. This boosts efficiency, letting employees handle inventory tasks from just about anywhere in the warehouse or store.

RFID Tag Tracking

RFID tag tracking takes inventory management to the next level. It uses radio frequency identification to track items without needing to see them directly. With RFID technology, you can scan multiple items at once, which seriously cuts down the time it takes to do inventory counts.

Integration with Inventory Database

With our software, you’ll make sure all the scanned data gets synced up right away with the central inventory database. This means stock levels, locations, and item details get updated in real-time.

Barcode Scanning and RFID Integration

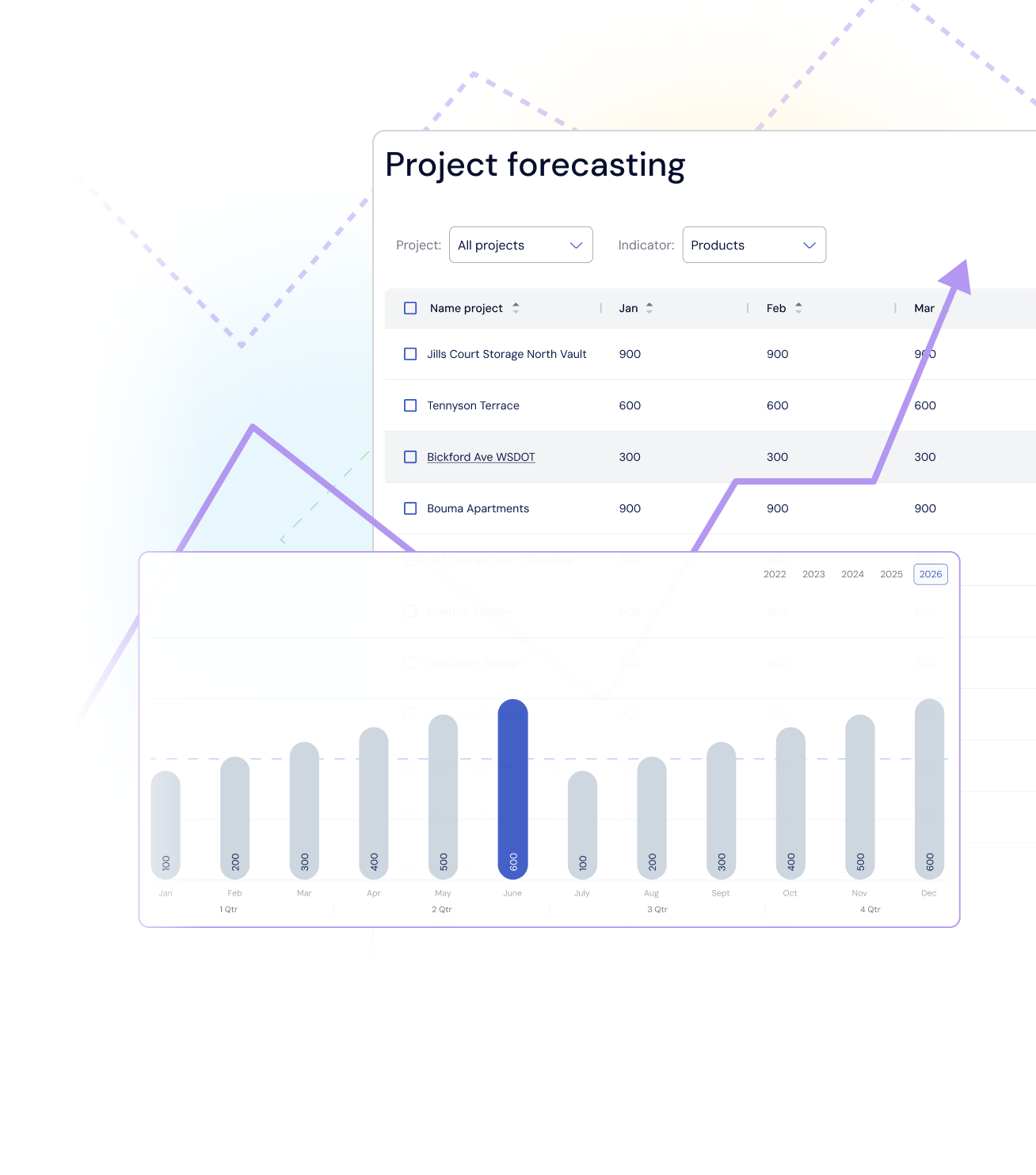

Demand Forecasting and Replenishment Planning

Historical Data Analysis

This feature takes a peek at old sales numbers, seasonal trends, and outside factors to guess what demand will look like in the future. It considers promotional events, market conditions, and product lifecycles. By checking out these historical patterns, you can make smarter choices about how much stock to keep and when to restock.

Automated Replenishment Suggestions

Get handy recommendations for restocking based on what’s expected to sell. These suggestions help keep your inventory just right, making sure you’ve got the perfect amount of stock when you need it.

Seasonal Demand Adjustment

This feature is great for helping you prepare for busy seasons so you can have enough stock on hand while avoiding excess during the slower times. Seasonal demand adjustment makes inventory planning smoother and keeps your stock levels correct all year long.

Demand Forecasting and Replenishment Planning

Warehouse Management and Optimization

Space Utilization Planning

Our inventory management software can recommend the smartest ways to arrange items, considering how often they’re picked and how they relate to each other. When done well, this can increase your storage capacity and optimize your warehouse operations.

Pick Path Optimization

Pick path optimization features help to identify the best routes for picking orders in the warehouse. Your staff won’t have to spend as much time or move as far when fulfilling orders. By optimizing the pick paths, you can get more done, save on labor costs, and speed up order processing.

Inventory Slotting

Ensure the items people purchase most often are easy to get to and that related items are stored close to each other. Good inventory slotting cuts down on pick times, reduces travel distances, and streamlines overall productivity in the warehouse.

Warehouse Management and Optimization

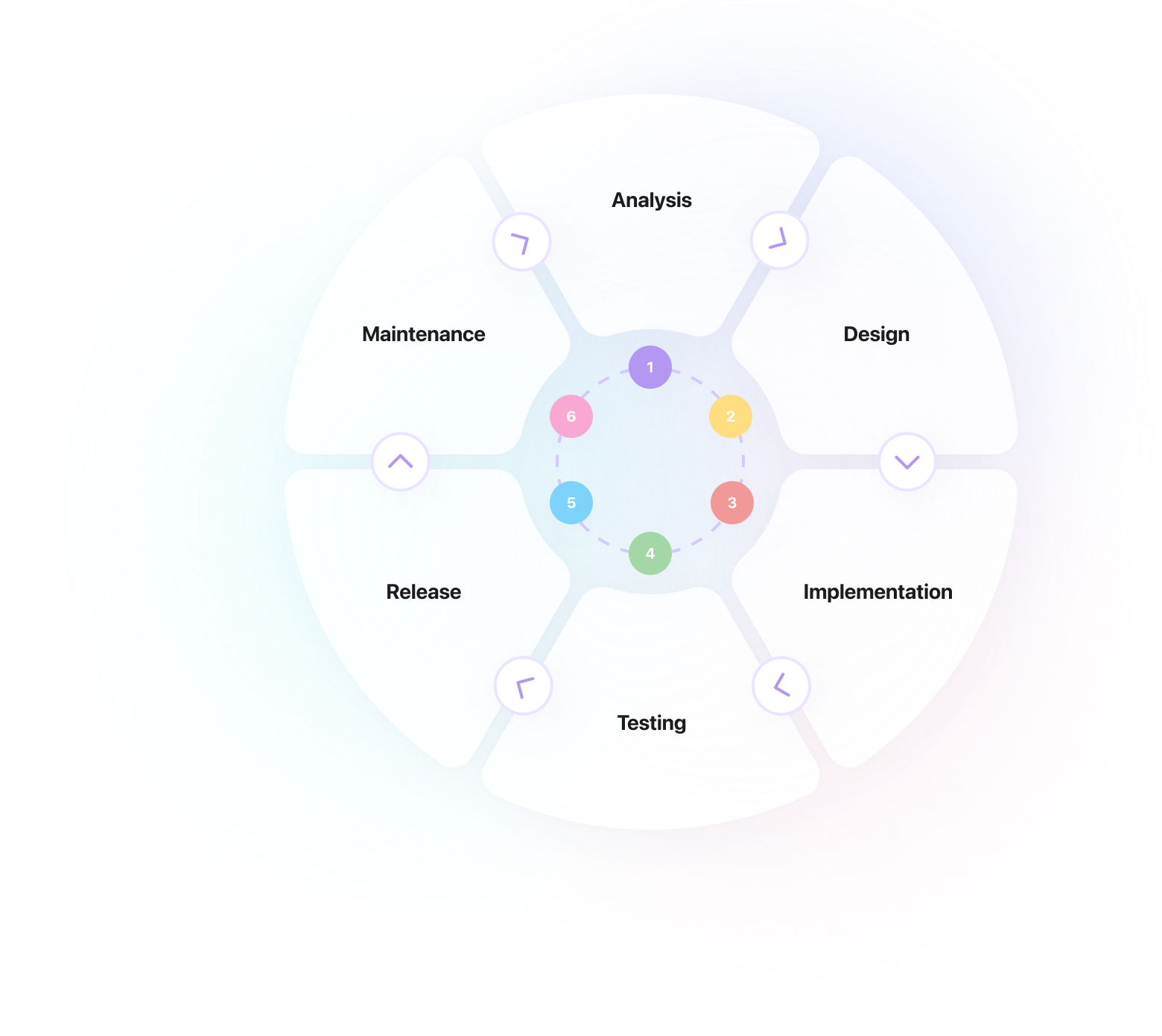

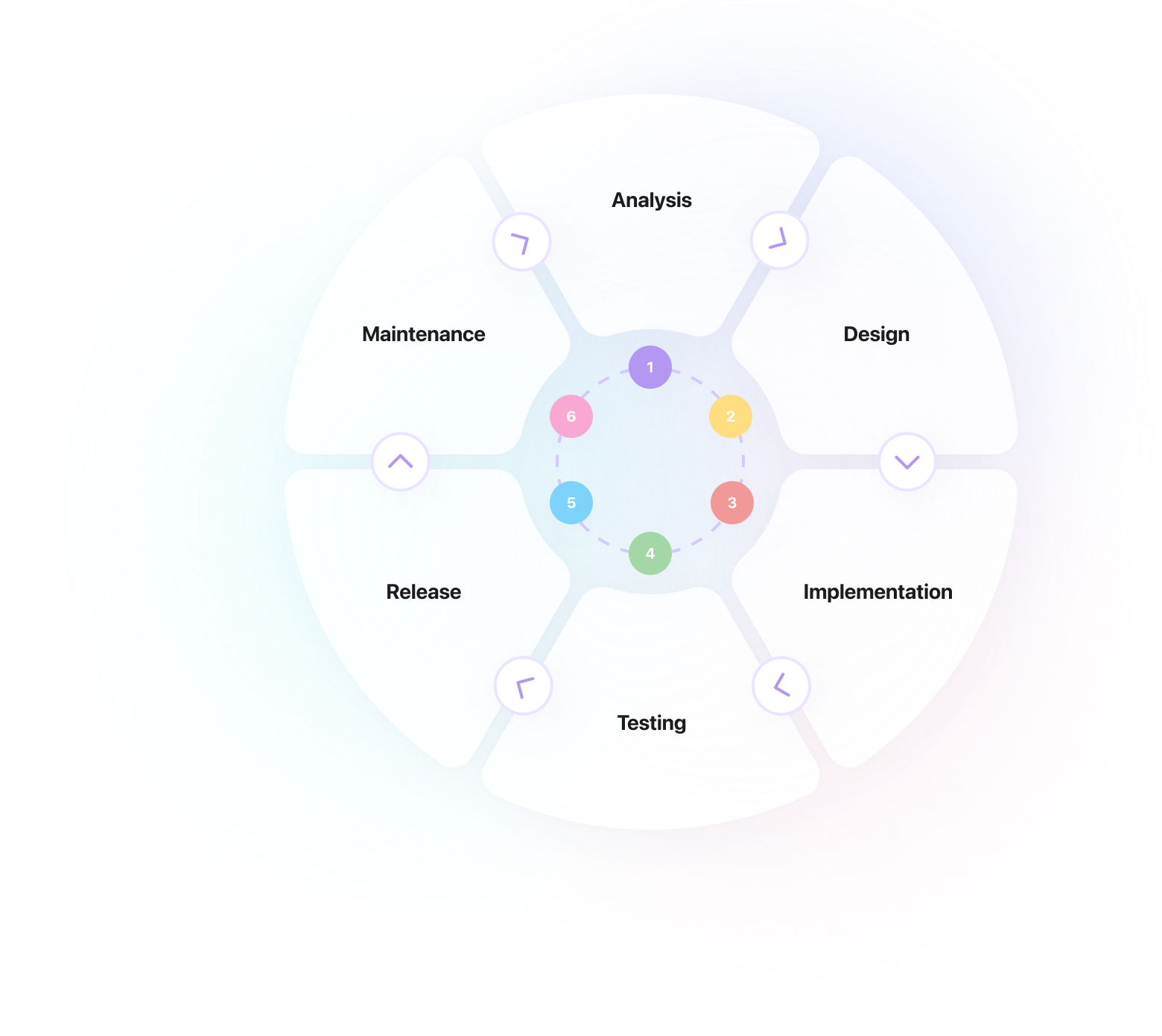

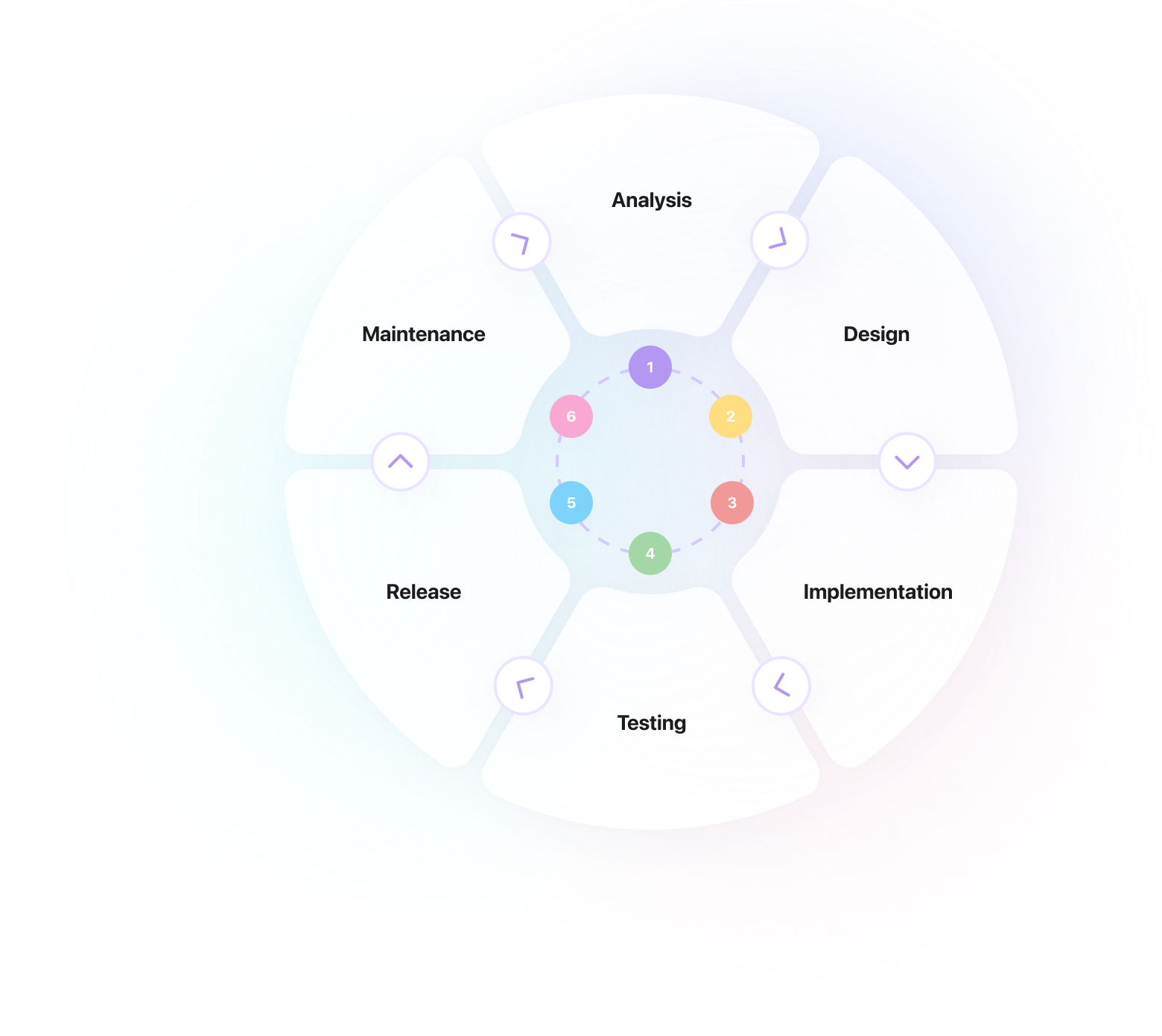

Inventory Software Development Process

Our inventory management software development process is structured yet flexible, so our experts can meet your specific needs while keeping our efficiency and quality up to par.

1. Consultations and Requirements Analysis

2. Design and Prototyping

3. Development and Implementation

4. Testing and Quality Assurance

5. Deployment and Support

Technologies We Use in Software Development

When we’re working on our inventory management software, we use the latest tech to make sure our solutions are strong, scalable, and perform as needed.

Reviews

“They took extra time to ensure that our frontend developer could easily implement the wireframes.”

“The quality of Uitop’s work was really outstanding. Uitop impressed with the quality of their designs, which received positive feedback from various users.”

“They took way more responsibility than we asked and we were so happy with the results of all their work. Uitop was easy to work with, flexible, and valuable to our company.”

“We were really happy with the whole process. The team’s workflow was smooth; their designers communicated well and responded to questions promptly.”

“We’re most impressed with Uitop’s ability to come up with a system to be able to bring design solutions.”

“Uitop delivers high-quality results on time through effective communication. They were patient and easy to work with throughout the development process.”

Inventory Management Software Development Case Studies

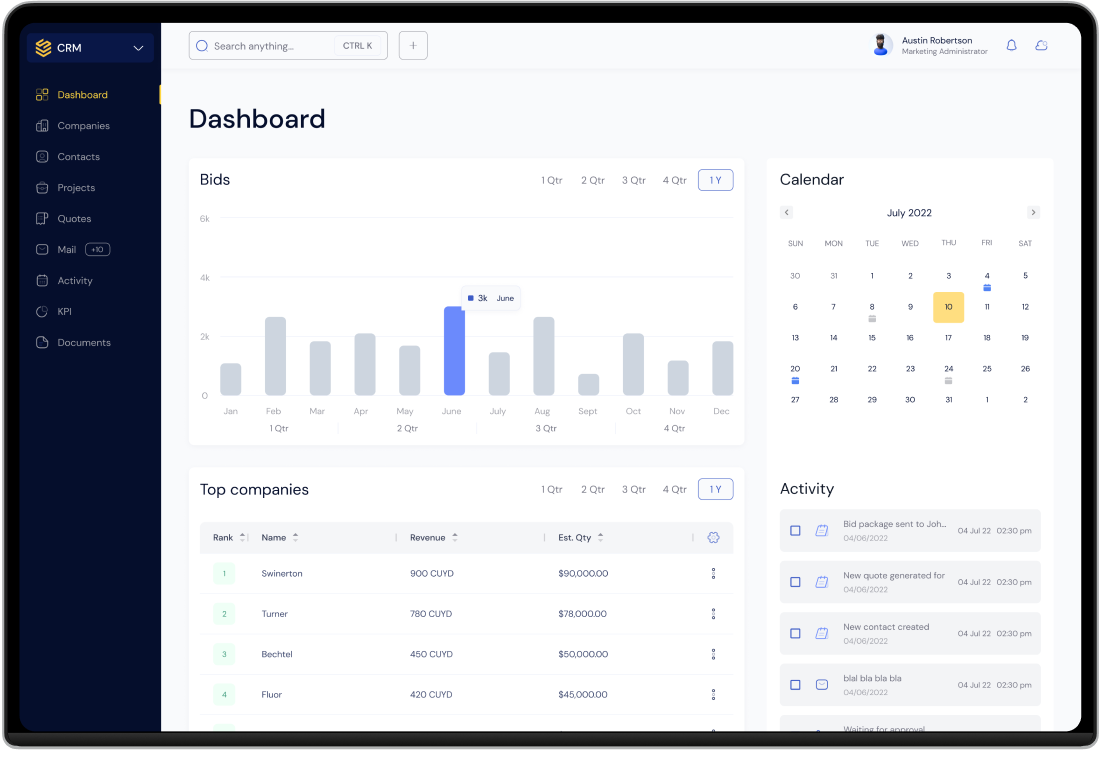

We redesigned a complex construction ERP software which raised $3.4M

We improved Slabstack’s ERP platform, making complicated processes easier to use and improving how inventory management is handled. These changes brought in more corporate clients via improved sales.

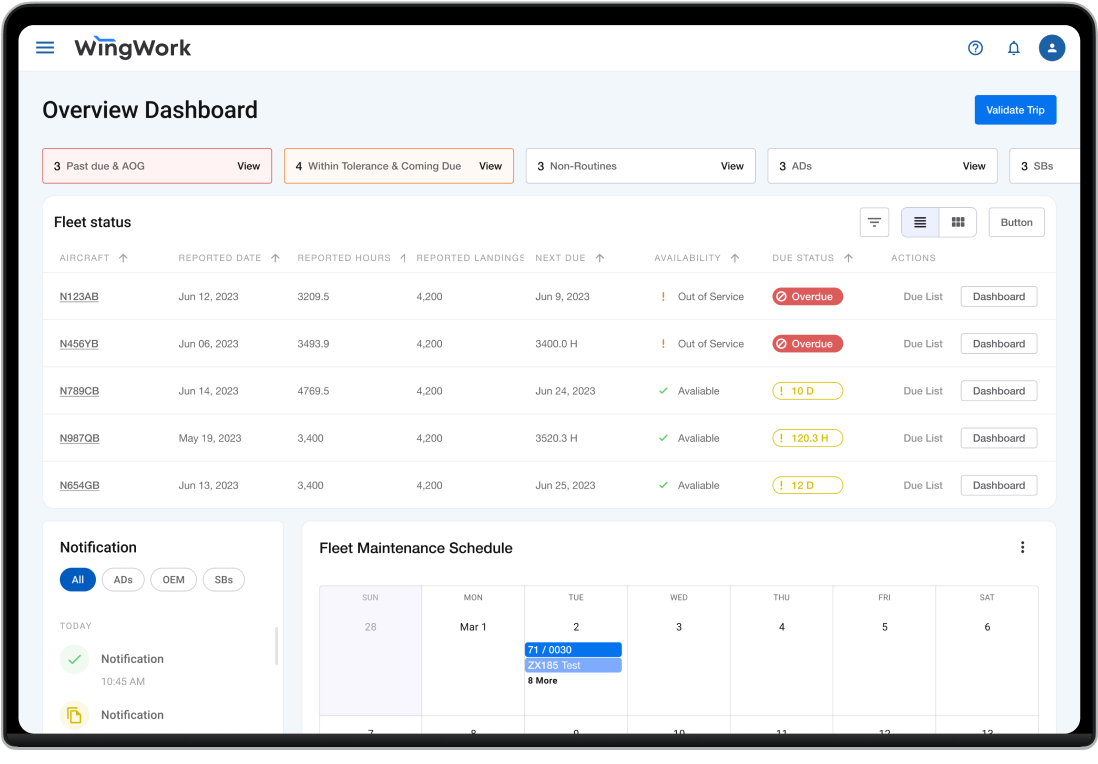

We redesigned the inventory feature for a B2B aviation SaaS

The previous design of WingWork’s software for the aviation industry causes a lot of issues with inventory management, making it difficult to use and limiting client growth. By refining the interface step by step, we helped WingWork attract its first clients and secure a $3.25 million investment.

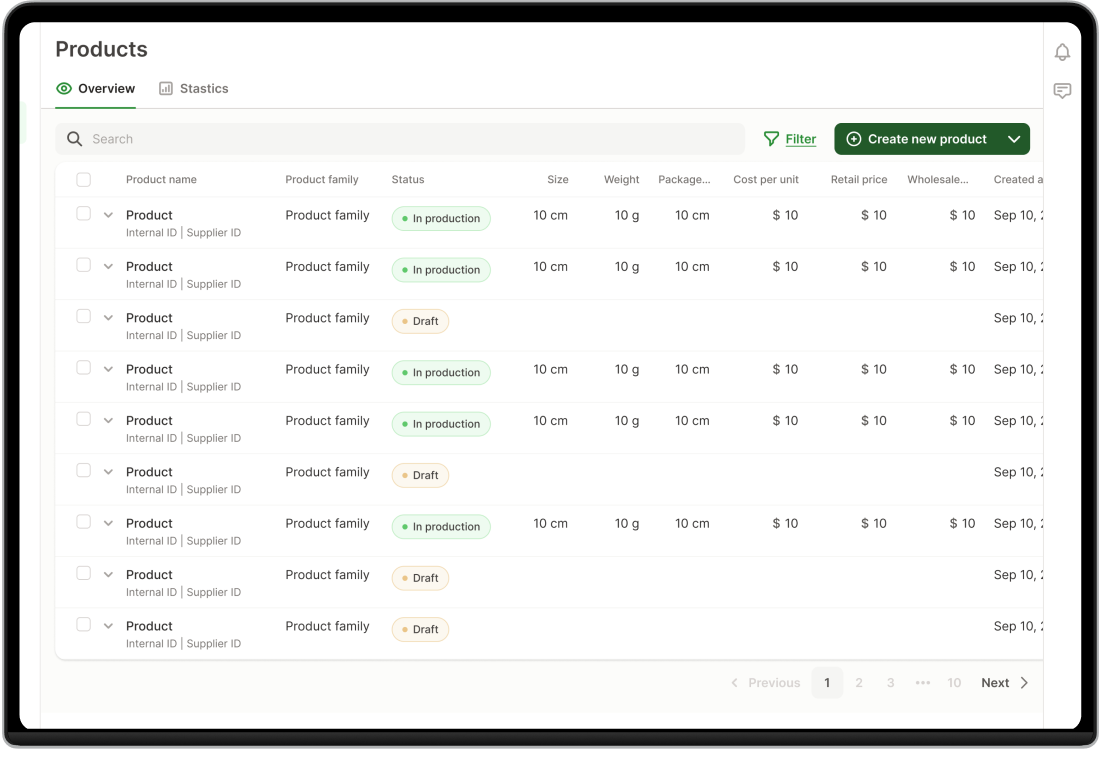

We improved Inventory management for the food manufacturing industry

The food production industry often faces challenges in managing perishable products, making inventory management more difficult. We solved this challenge by redesigning the user interface of inventory management software, receiving 96% demo users to customers conversion.

Why You Can Count on Us for Your Inventory Management Software Development

FAQs

What’s custom inventory management software, and how’s it different from regular one?

Custom inventory management software is specially made to fit your company needs and workflow. Unlike standard solutions you can just buy off the shelf, this type gives you more flexibility, can grow with your business, and fits better with your specific challenges.

How long does it generally take to create custom inventory management software?

The time it takes can change based on how complicated your needs are. On average, it usually takes about 3 to 6 months from the first engagement to the final launch.

Can we make custom inventory management software work with the systems we already have?

One of the best things about custom software is that it can easily connect with your existing systems. Whether you have an ERP, CRM, e-commerce platform, or accounting software, we can set up your inventory management system so that it works with these tools.

What kind of support can we expect after the software is up and running?

We offer solid support after the deployment. This means we handle troubleshooting, fix bugs, and conduct system updates. Plus, we have ongoing maintenance packages, user training, and we can add new features or make changes as your business grows.

Let’s Talk!

“They took extra time to ensure that our frontend developer could easily implement the wireframes.”

“The quality of Uitop’s work was really outstanding. Uitop impressed with the quality of their designs, which received positive feedback from various users.”

Order Custom Inventory Software Today!

Start improving your inventory management today — just contact us for a consultation, and see how our custom software can benefit your business.